Production Lines for Short-Cut and Long-Cut Pasta, Nests and Lasagne

- Short Cut Pasta Semiautomatic Line

- Short Cut Pasta Nests and Lasagne Semiautomatic Line

- Long Cut Pasta Semiautomatic Line

Short Cut Pasta Semiautomatic Line

Anselmo LTA technology, for the short cut and special pasta semiautomatic production is characterized by a traditional static drying system.

Thanks to the Anselmo LTA design study, the technological choices are aimed to obtain an excellent product, a careful attention to detail, as well as increasing the systems’ working lives.

The traditional press, with long mixing times and a slow extrusion phase, ensures an excellent product ready for shaping.

The flat or inclined cutting system makes it possible to have short cut and special shapes of different lengths.

The shaker pre-dryer, appropriately sized, prevents sticking on any short cut pasta shape and shorten the drying timing in static cell.

After an appropriately timed pre-drying, the product reaches the drying and stabilization stage with consequent final cooling, by an innovative system.

Total drying time amongst 12 and 16 hours, according to the produced shapes.

Thanks to its simple and intuitive user interface, the fully automated process control management system guarantees an excellent control of all line’s parameters during every process stage.

This system allows production lots traceability and production parameters display via Internet.

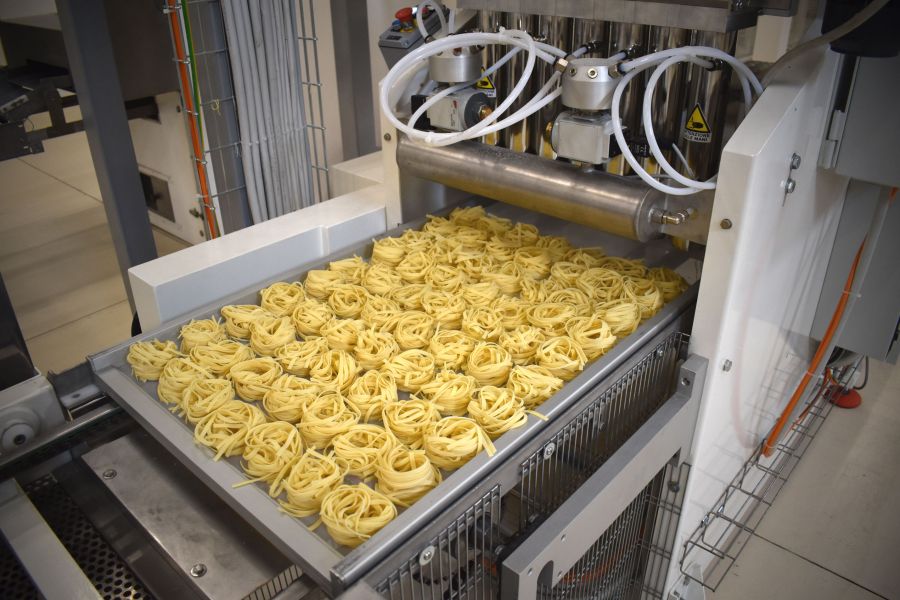

Short Cut Pasta Nests and Lasagne Semiautomatic Line

Anselmo LTA technology for the short cut, nests and lasagne semiautomatic production is characterized by a traditional static drying system.

Thanks to the Anselmo LTA design study, the technological choices are aimed to obtain an excellent product, a careful attention to detail, as well as increasing the systems’ working lives.

The traditional press, with long mixing times and a slow extrusion phase, ensures an excellent product ready for shaping.

The flat or inclined cutting system makes it possible to have short cut and special shapes of different lengths.

The product forming machine makes it possible to have nests and lasagne of different sizes and weight.

The shaker pre-dryer, appropriately sized, prevents sticking on any short cut pasta shape and shorten the drying timing in static cell.

After an appropriately timed pre-drying, the product reaches the drying and stabilization stage with consequent final cooling, by an innovative final cooling system.

The total drying time can vary from 12 and 16 hours, according to the produced shapes.

Thanks to its simple and intuitive user interface, the fully automated process control management system guarantees an excellent control of all line’s parameters during every process stage.

This system allows production lots traceability and production parameters display via Internet.

Long Cut Pasta Semiautomatic Line

Anselmo LTA technology, for the long cut semiautomatic production is characterized by a traditional static drying system. Thanks to the Anselmo LTA design study, the technological choices are aimed to obtain an excellent product, a careful attention to detail, as well as increasing the systems’ working lives.

The traditional press, with long mixing times and a slow extrusion phase, ensures an excellent product ready for shaping.

After an appropriately timed pre-drying, the product reaches the drying and stabilization stage with consequent final cooling, by an innovative system.

Total drying time amongst 12 and 16 hours, according to the produced shapes.

Thanks to its simple and intuitive user interface, the fully automated process control management system guarantees an excellent control of all lines' parameters during every process stage.

This system allows production lots traceability and production parameters display via Internet.