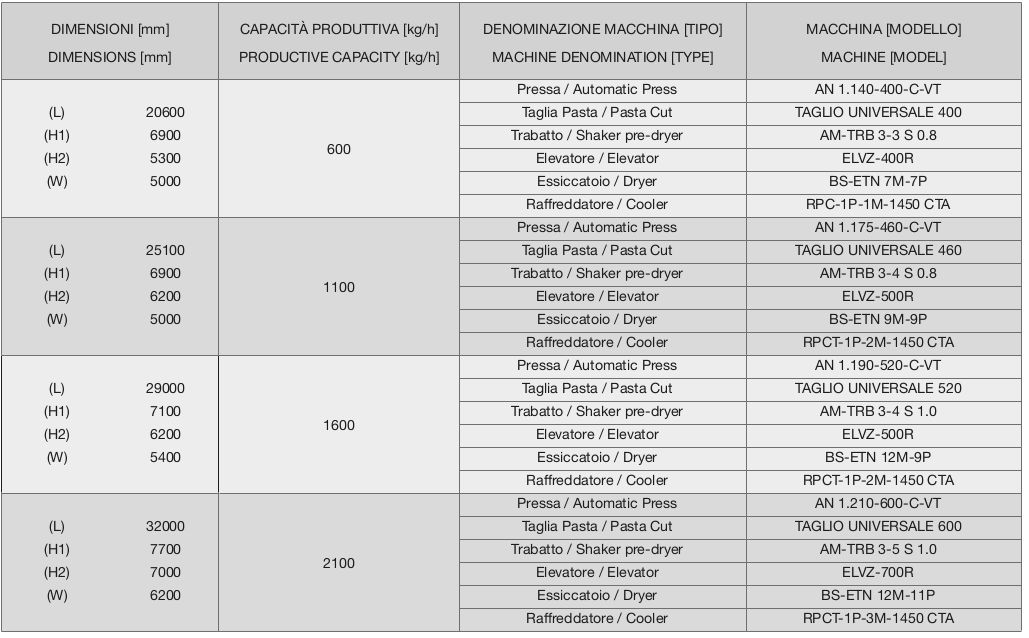

• The total vacuum press performs mixing of raw materials,

water and additives required for the kneading, with subsequent extrusion and forming of the product into the desired product shape.

• Automatic device suitable to cut all types of pasta (pastina, short pasta, penne)

• Three-level shaker pre-dryer, entirely in stainless steel with high thermal power to obtain an excellent product treatment, designed to prevent its fall out.

• Elevators to transport product from one level to another one with stainless steel mesh or metal sheet buckets and food grade plastic material heads.

• Single room dryer (pre-drying - drying - stabilization).

Product transport system inside the dryer, made with single-wire mesh plastic belts, suitable for high temperature, aluminium support and sliding wheels, to maximize air flow and for the reduction of energy consumption.

No lubrication is required for this conveyor system.

High permeability of the product transport system, high efficiency of the ventilation system and technological management ensure the production of a wide range of products.

• One passage Cooler, made with metallic aluminium belt and stainless steel mesh.

The closed-circuit ventilation system and the high permeability of the conveying system, ensure an excellent cooling of the product and a reduction in terms of energy consumption.

• Electrical control panels are built according to the highest quality standards available on the market.

• Maximum level of automation, for PLC process control and PC supervision.

The technique

• The total vacuum press performs mixing of raw materials,

water and additives required for the kneading, with subsequent extrusion and forming of the product into the desired product shape.

• Automatic device suitable to cut all types of pasta (pastina, short pasta, penne)

• Three-level shaker pre-dryer, entirely in stainless steel with high thermal power to obtain an excellent product treatment, designed to prevent its fall out.

• Elevators to transport product from one level to another one with stainless steel mesh or metal sheet buckets and food grade plastic material heads.

• Single room dryer (pre-drying - drying - stabilization).

Product transport system inside the dryer, made with single-wire mesh plastic belts, suitable for high temperature, aluminium support and sliding wheels, to maximize air flow and for the reduction of energy consumption.

No lubrication is required for this conveyor system.

High permeability of the product transport system, high efficiency of the ventilation system and technological management ensure the production of a wide range of products.

• One passage Cooler, made with metallic aluminium belt and stainless steel mesh.

The closed-circuit ventilation system and the high permeability of the conveying system, ensure an excellent cooling of the product and a reduction in terms of energy consumption.

• Electrical control panels are built according to the highest quality standards available on the market.

• Maximum level of automation, for PLC process control and PC supervision.