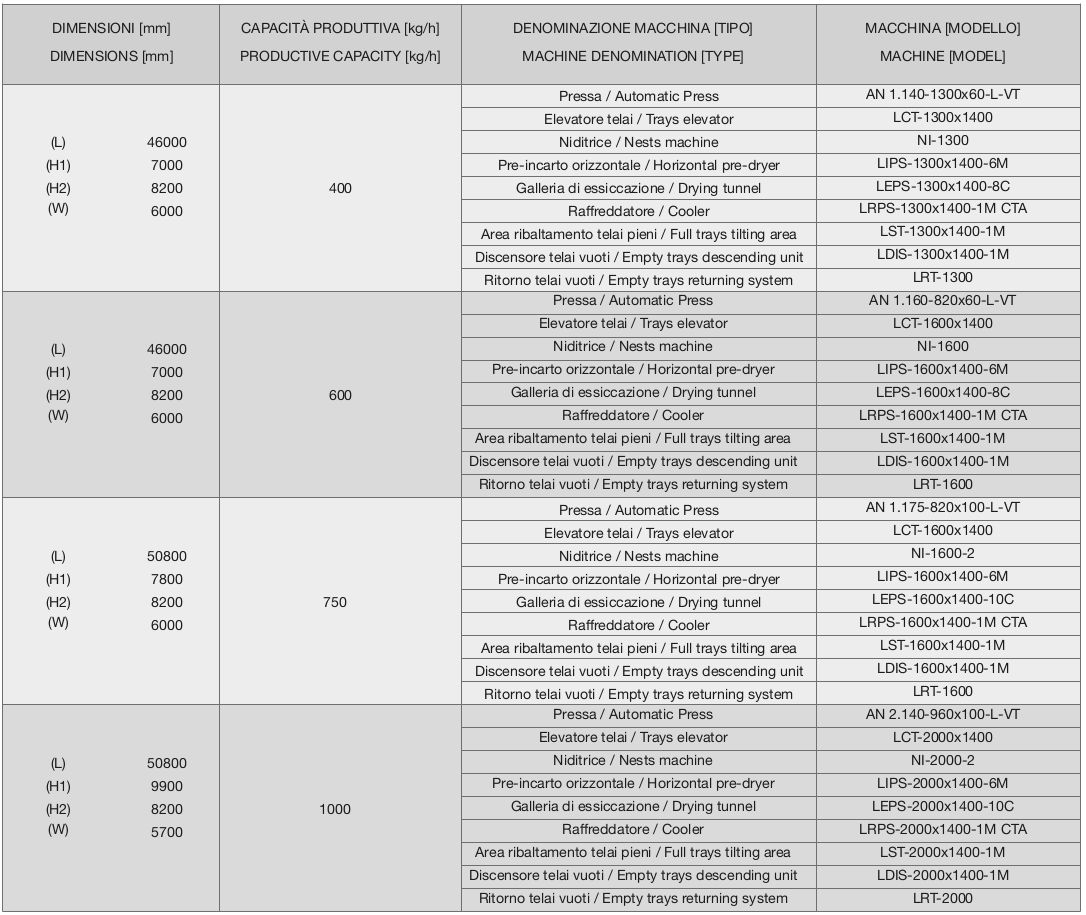

• The traditional press performs mixing of raw materials,

water and additives required for the kneading, with subsequent extrusion and forming of the product into the desired product shape.

• Trays automatic loading system to the shaping machine.

• "Nests" and "matasse" shaping machine.

• Single tier dryer in various sizes depending on the product.

High permeability of the product

transport system, high efficiency of the ventilation system and technological management ensure

the production of a wide range of products.

• Drying tunnel (pre-dryer - dryer - stabilization) with vertical modules.

High permeability of

product movement trays, high efficiency of the ventilation system and technological

management, ensuring a wide range of products realization.

• Cooler with one or more trays.

The closed-circuit ventilation system and the high permeability of the conveying system, ensure an excellent cooling of the product and a reduction in terms of energy consumption.

• Buffer for storing trays with product.

• Product unloading system and trays cleaning.

• Buffer for storing trays without product.

• Descender for empty trays.

• Automatic unit for trays drop-down and trays return feeding system.

• Trays for pasta conveying, built with stainless steel external assembly, anodised aluminium

profiles and 90 °C thermo-resistant polyester net.

• Electrical control panels are built according to the highest quality standards available on the

market.

• Maximum level of automation, for PLC process control and PC supervision.

The technique

• The traditional press performs mixing of raw materials,

water and additives required for the kneading, with subsequent extrusion and forming of the product into the desired product shape.

• Trays automatic loading system to the shaping machine.

• "Nests" and "matasse" shaping machine.

• Single tier dryer in various sizes depending on the product.

High permeability of the product

transport system, high efficiency of the ventilation system and technological management ensure

the production of a wide range of products.

• Drying tunnel (pre-dryer - dryer - stabilization) with vertical modules.

High permeability of

product movement trays, high efficiency of the ventilation system and technological

management, ensuring a wide range of products realization.

• Cooler with one or more trays.

The closed-circuit ventilation system and the high permeability of the conveying system, ensure an excellent cooling of the product and a reduction in terms of energy consumption.

• Buffer for storing trays with product.

• Product unloading system and trays cleaning.

• Buffer for storing trays without product.

• Descender for empty trays.

• Automatic unit for trays drop-down and trays return feeding system.

• Trays for pasta conveying, built with stainless steel external assembly, anodised aluminium

profiles and 90 °C thermo-resistant polyester net.

• Electrical control panels are built according to the highest quality standards available on the

market.

• Maximum level of automation, for PLC process control and PC supervision.