• Total vacuum press for mixing raw materials,

water and any necessary additives to the dough with subsequent product extrusion and forming in the desired shape.

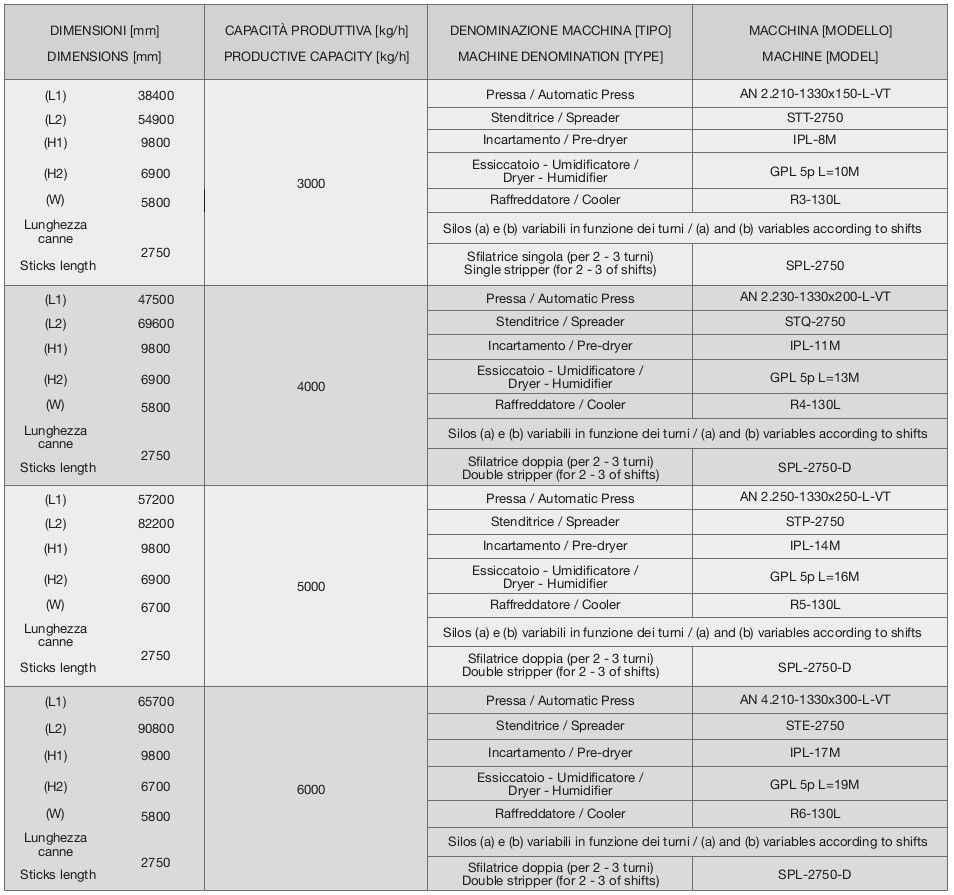

• Spreader with 1 to 6 sticks, according to the line's production capacity.

The spreader has the function of distributing simultaneously fresh spaghetti on the stick, equalizing the length.

• Single-tier modular stainless-steel pre-dryer with sticks conveyor chain.

The high efficiency of the ventilation system and the technological managing allow the production of a wide range of products, reducing energy consumption.

• Modular drying unit five tiers, made in stainless steel, with new sticks conveyor chain.

The high efficiency of the ventilation system, separated by drying and stabilization sections, allows the production of a wide range of products and the reduction of energy consumption.

• Stainless steel humidifier with stainless steel chains conveyor system.

The high efficiency of the ventilation system and the injection of treated water allow to get an elastic product.

• Stainless-steel gradual cooler, with stainless steel chains conveyor system, physically separated from the dryer’s warm zone.

The high efficiency of the ventilation system and the injection of treated water allow to get an excellent product cooling.

• Finished product storage silo, in different sizes and tiers, with automatic loading and unloading system.

• Single or double stripper, according to line production or packaging shifts.

The stripper function is to remove the dried spaghetti from the stick and cut them to fit in the package.

• 2750 mm sticks, made of anodized aluminium with micro-casted stainless-steel hooks.

• Electrical control panels are built according to the highest quality standards available on the market.

• Maximum level of automation, for PLC process control and PC supervision.

The technique

• Total vacuum press for mixing raw materials,

water and any necessary additives to the dough with subsequent product extrusion and forming in the desired shape.

• Spreader with 1 to 6 sticks, according to the line's production capacity.

The spreader has the function of distributing simultaneously fresh spaghetti on the stick, equalizing the length.

• Single-tier modular stainless-steel pre-dryer with sticks conveyor chain.

The high efficiency of the ventilation system and the technological managing allow the production of a wide range of products, reducing energy consumption.

• Modular drying unit five tiers, made in stainless steel, with new sticks conveyor chain.

The high efficiency of the ventilation system, separated by drying and stabilization sections, allows the production of a wide range of products and the reduction of energy consumption.

• Stainless steel humidifier with stainless steel chains conveyor system.

The high efficiency of the ventilation system and the injection of treated water allow to get an elastic product.

• Stainless-steel gradual cooler, with stainless steel chains conveyor system, physically separated from the dryer’s warm zone.

The high efficiency of the ventilation system and the injection of treated water allow to get an excellent product cooling.

• Finished product storage silo, in different sizes and tiers, with automatic loading and unloading system.

• Single or double stripper, according to line production or packaging shifts.

The stripper function is to remove the dried spaghetti from the stick and cut them to fit in the package.

• 2750 mm sticks, made of anodized aluminium with micro-casted stainless-steel hooks.

• Electrical control panels are built according to the highest quality standards available on the market.

• Maximum level of automation, for PLC process control and PC supervision.